chapter four

Environment

Working towards

reducing our footprint.

Other sustainability objectives & projects

Next to our Peak Programme we want to maintain a high standard of reducing the environmental impact of our supporting activities, such as our office buildings and car fleet. Also, we contribute to a more sustainable world via donating to tree planting initiatives.

Via these initiatives we offset a part of our carbon footprint. Together with Land Life we help restore land and nature via tree planting programs in Europe. We have now donated more than 100,000 trees in the last four years.

Projects

Impact area 6 & 7

PRS Green Label, which stimulates pallet recovery with converters.

Connected-Load Carrier to make our load carriers traceable.

IPP Pallet Recovery Communications Campaign.

Improving pallet lifespan is key to our sustainability ambitions. By enhancing repair and reusability, we boost performance. Digitalising assets with Connected Load Carrier helps track and optimise supply chains and reducing loss. Unique identifiers like RFID, QR, and barcodes further enhance control over pallet usage and location.

Even while we are extending the lifetime of load-carriers, they will reach the end of their life span eventually. It is our goal to make sure these decommissioned load-carriers are processed in the best way possible.

IPP Pallet Recovery Communications Campaign

RUDi,

the award winning ReUsable Display from IPP Germany

Projects

Projects

procurement of new-load carriers

Reduce transport and depot emissions

Impact area 5

Impact area 3 & 4:

Impact area 1 & 2

IPP’s sustainable transport program which has been awarded with the European two-star Lean & Green rating.

IPP France's FRET21 Programme to reduce carbon emissions from transport, see case study here.

PAKi HVO pilot project with our haulier Scholz focusing on green transport solutions, see case study here.

Growing our business and help customers make use of pooling instead of less sustainable alternatives such as one-way load-carriers.

Introduce pooling innovations in one-way load-carrier markets, for example RUDi, the ReUsable Display by IPP Germany.

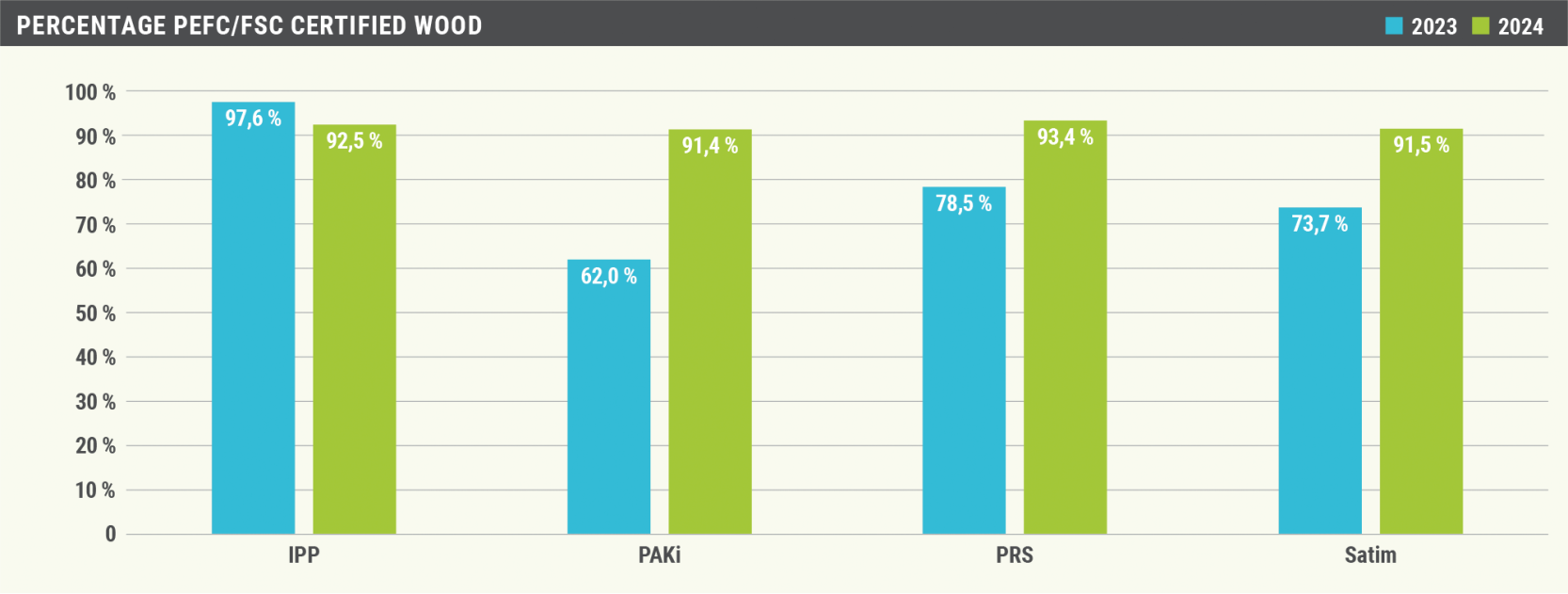

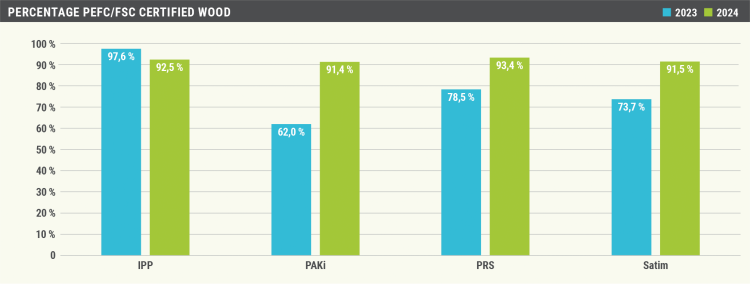

We believe partnerships and circularity are key to offering our customers an effective and sustainable pooling network. That is why we are creating a sustainable and ethical supply chain with strong suppliers and partners. We do this by stimulating our (new) suppliers to act and improve on sustainability and social topics but also by sourcing in a sustainable manner. Related to the procurement of new-load carriers we are now above 90 % of purchased certified wood for al divisions. Our goal is to work towards 100 % certified pallets in 2030. In 2024, IPP faced a decline in certification due to an one-off urgent pallet procurement to cover customer needs. In 2024 we started a groupwide procurement program to improve the sustainability performance of our supply chain and suppliers.

Our goal for transport emissions is to improve efficiency, switch to cleaner transport types, but also by optimising our transport network. Depot partners play a vital role in our supply chain. These partners store, sort & repair our load-carriers. Our goal is to help depots in becoming more sustainable and reduce their footprint.

Increase the amount of CO₂e-emissions we avoid in the supply chain of our customers. These avoided emissions we call our ‘avoided emissions/Scope 4’ impact: we want to maximise the carbon savings that our customers realise by choosing a pooling system instead of using a less sustainable alternative (such as one-way pallets).

Peak programme

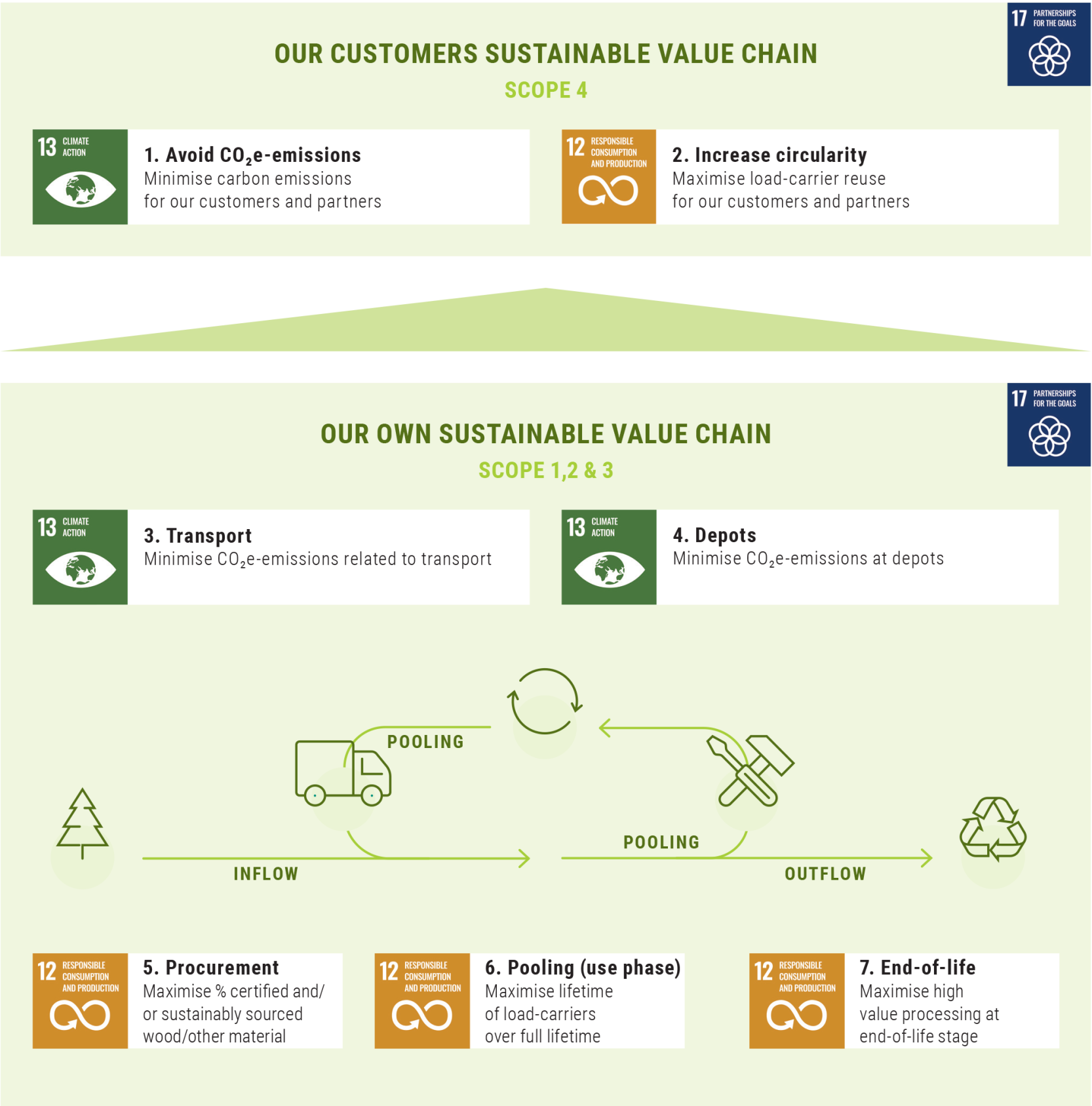

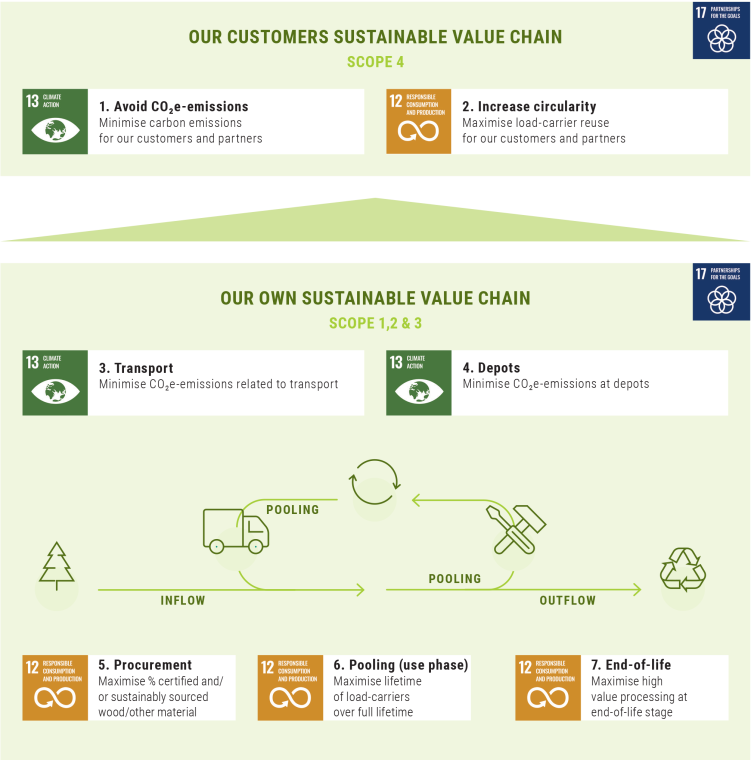

Our Peak Programme is two-folded, first focus is to increase Scope 4 (impact area 1 & 2) and secondly, we want to decrease Scope 1, 2 and 3 (impact area 3 - 7). Each Impact Area delivers a contribution to at least one of the Faber Development Goals.

The Peak Programme contains seven impact areas that enable the organisation to minimise the carbon footprint, maximising reuse and engaging in strategic partnerships to reach the sustainability targets. The overview below shows the progress per impact area.

Improving our positive impact

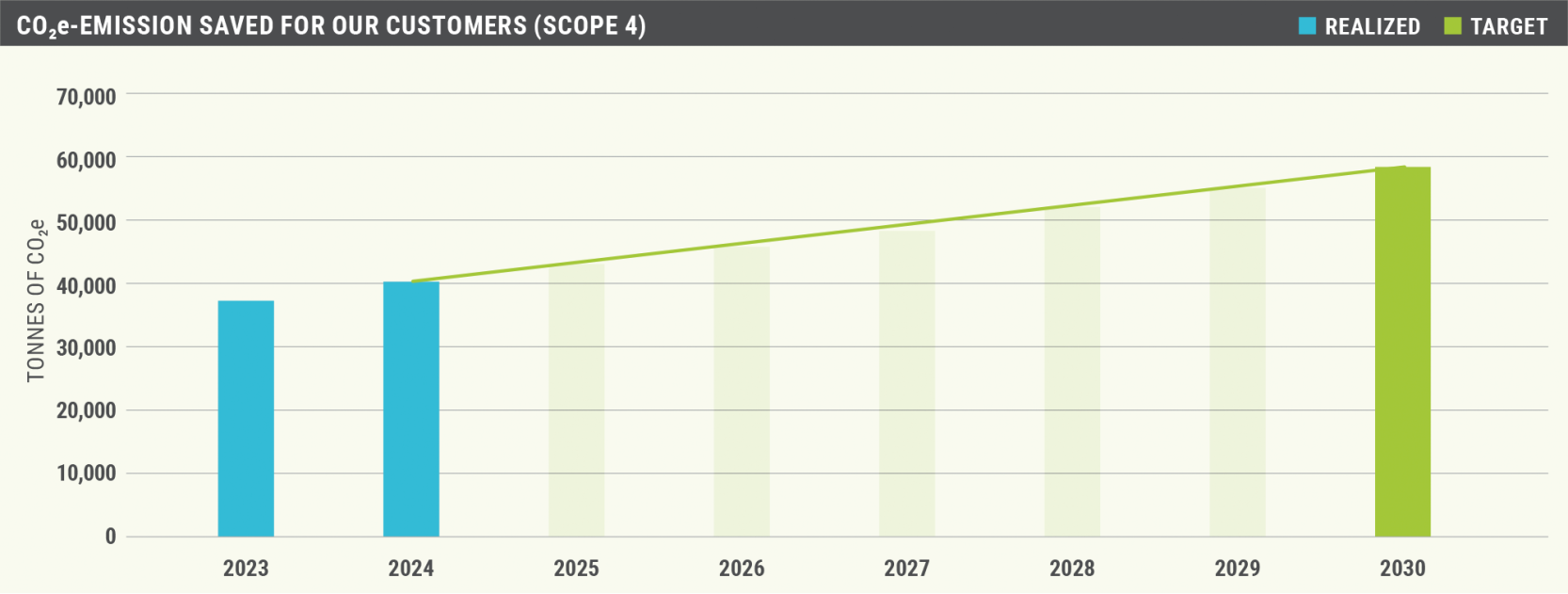

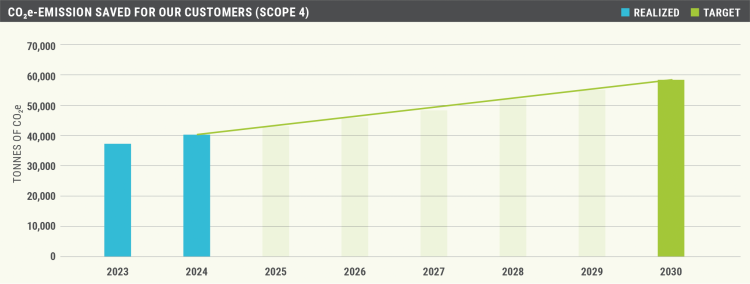

One of our goals is to increase the amount of CO₂e-emissions we avoid in the supply chain of our customers. In other words: we want to maximise the carbon savings that our customers realise by switching to our circular pooling system instead of using a less sustainable alternative (such as one-way pallets or a 1-to-1 exchange system). These savings customers realise we call our ‘Scope 4’.

In order to quantify these scope 4 emissions, we use the ‘Guidance on Avoided Emissions’ from the World Business Council for Sustainable Development (2023 version). Following this guideline we first investigate the savings per trip, which is done via comparative LCA studies. These studies were carried out in 2023 and 2024 according to ISO14040/44 and peer reviewed. The results of these savings per trip can be found in the Faber Group Sustainability Report 2023. Multiplying the savings per rotation by the number of trips on a yearly basis gives the yearly savings we realise for customers. In 2024 we were able to save an amount of more than 40,000 tonnes of CO₂e for our customers, which was an increase of 8 % in comparison to 2023; our aim is to save more than 58,000 tonnes of CO₂e on a yearly basis for our customers by 2030.

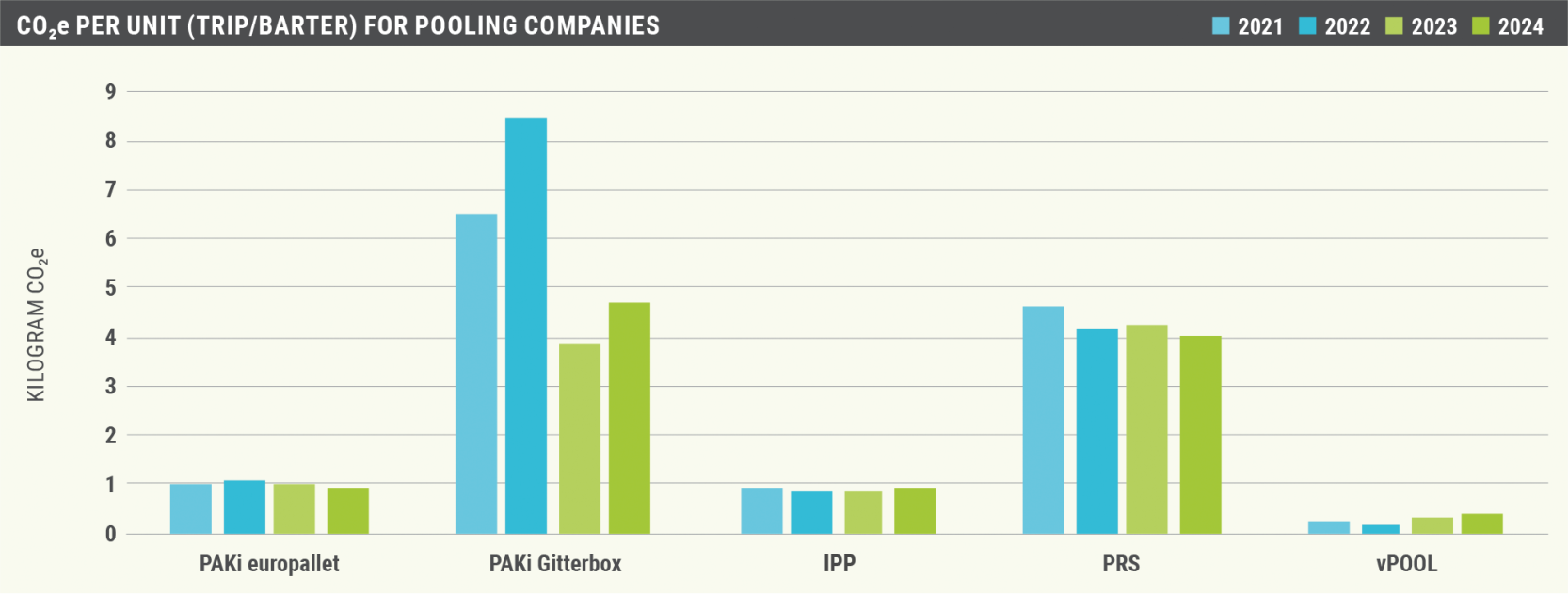

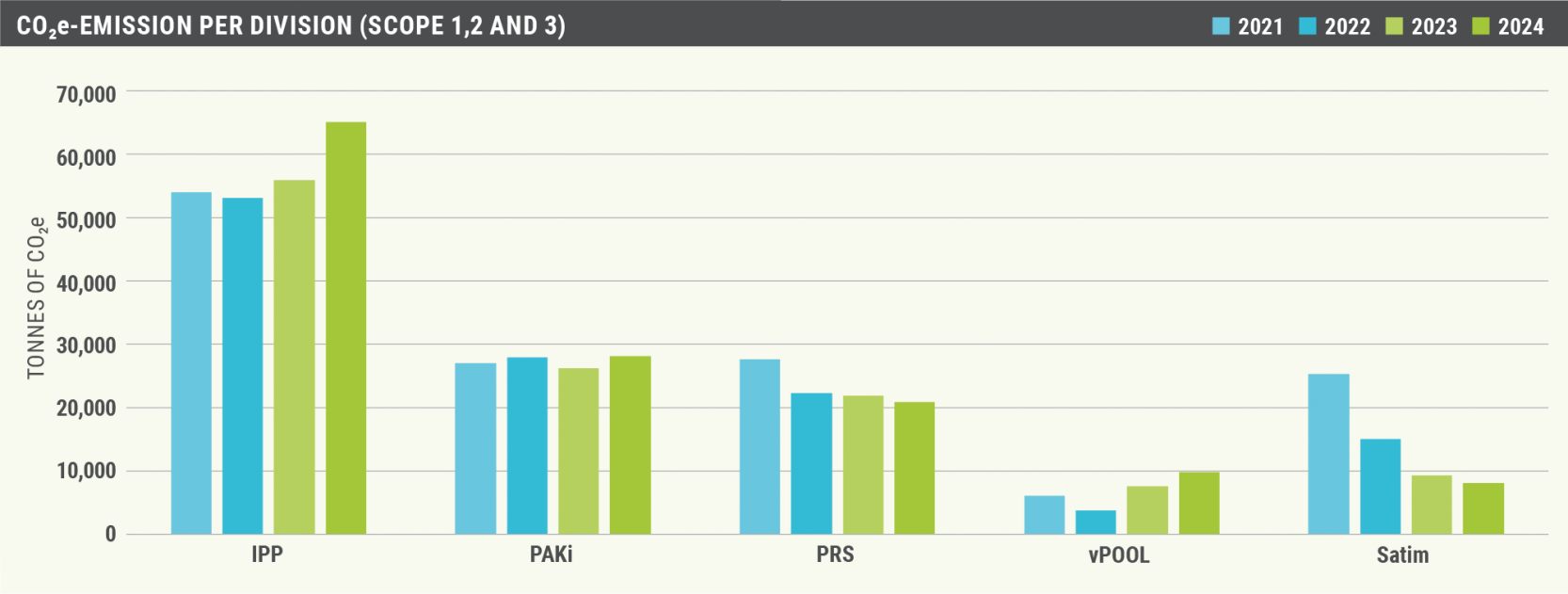

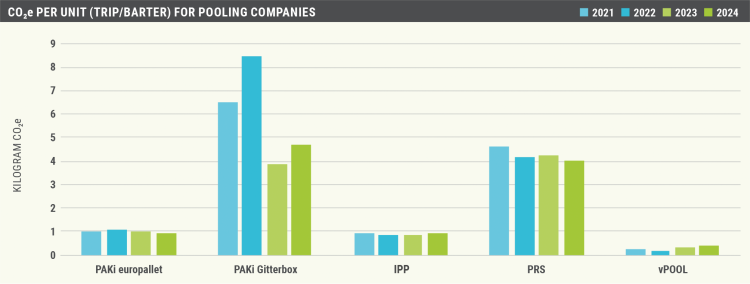

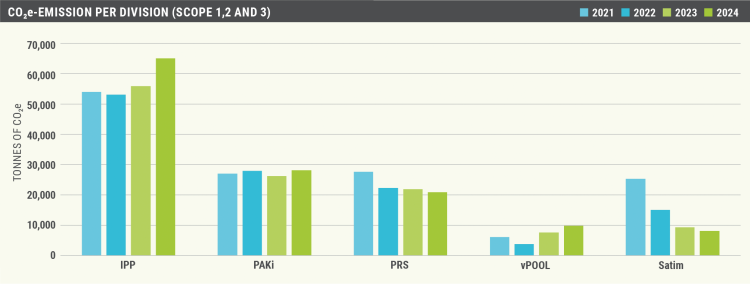

Footprint per division

As can be seen in the graphs, we have realised an overall lower footprint for our divisions PRS and SATIM, but an increase in absolute CO₂e-emissions for IPP, PAKi and vPOOL. Especially for SATIM the reduction is significant, this is mainly the result of less wood procurement in comparison to previous years. Since we are growing in number of trips and business, it is important to not only look at the absolute footprint, but also to look at the footprint per unit (per trip, barter or m3wood). This is a better indicator for the improvements we realize in our value chain. For PAKi and PRS we see a reduction in CO₂e-emissions per unit in comparison to the previous year and we are also on track to realise our target for 2030. IPP and vPOOL have a higher footprint in comparison to previous years. For vPOOL this has to do with a significant increase in the purchase of new load-carriers. Even though the total footprint for SATIM has gone down, the footprint per m3 wood went up. The main reason for the increase at SATIM is the longer distances trucks needed because new wood logging locations where selected in northern Scandinavia.

Scope 1, 2 and 3 emissions

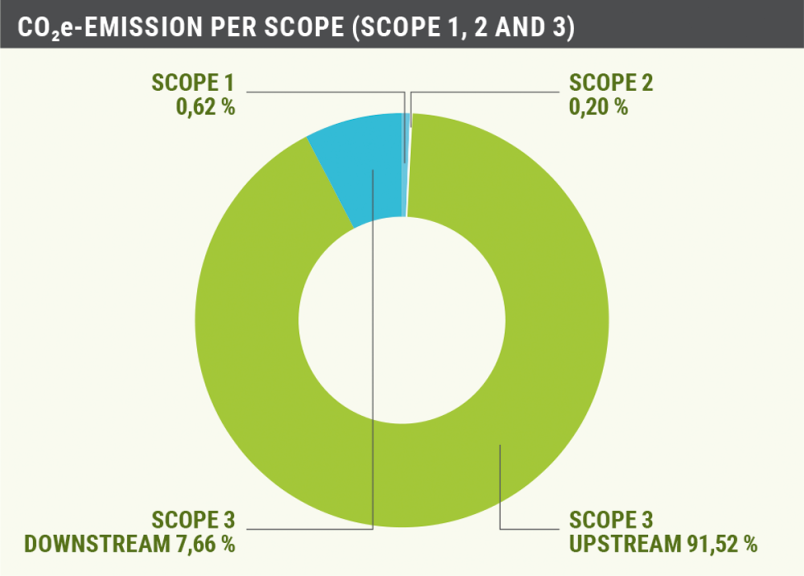

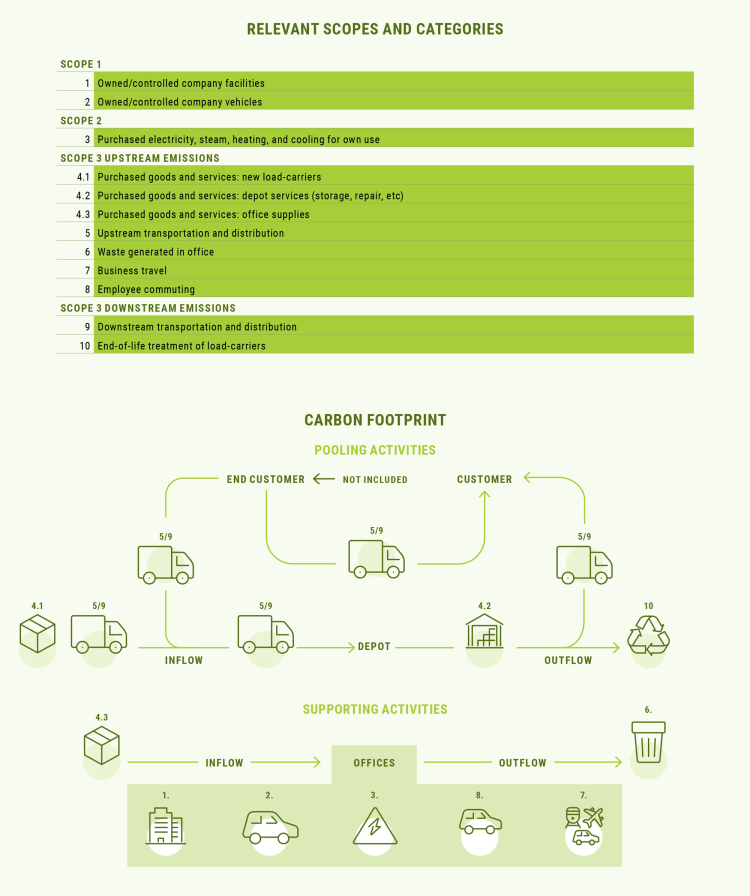

Scope 1: The direct emissions

These emissions are generated by our office buildings and company cars. Examples are gas usage for heating and fuel consumption of company cars.

Scope 2: Indirect emissions

The carbon emissions that are caused by generating electricity that we purchase and use in our own office buildings or company cars.

Scope 3: All other indirect emissions

Emitted in the value chain of the organisation. A distinction is made between upstream and downstream emissions.

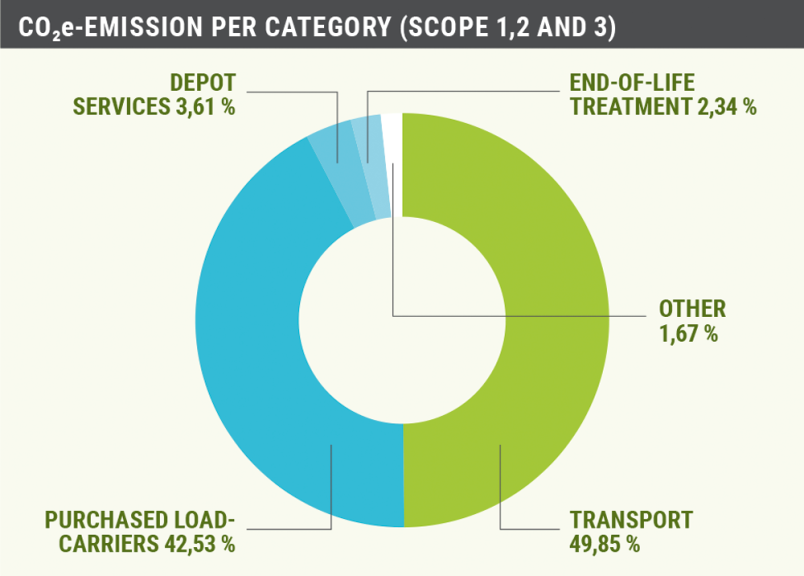

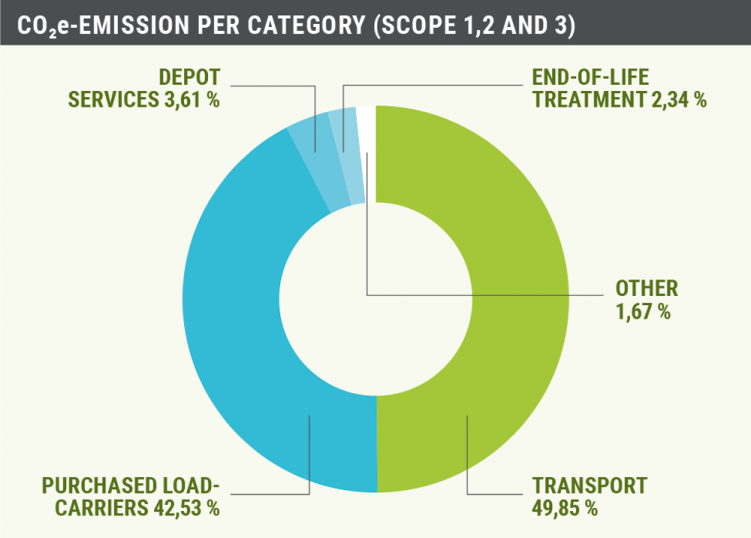

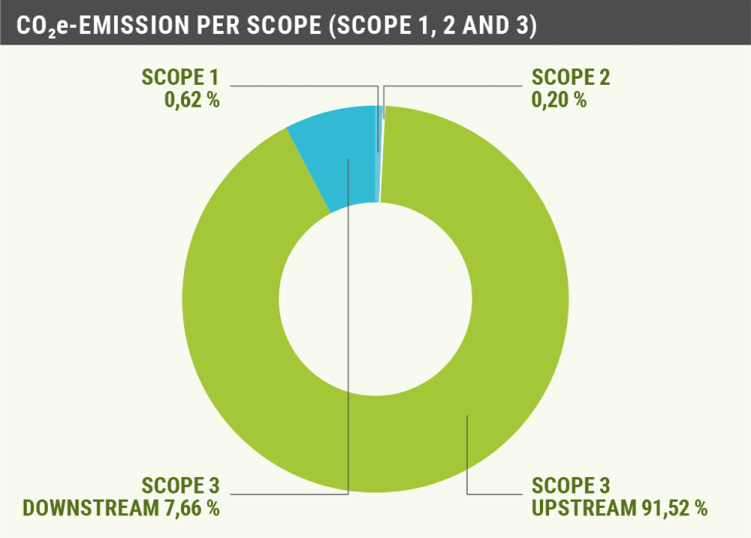

As indicated in the two pie charts – which is a breakdown of our average total footprint over the last four years – the main impact is caused by the production of new load carriers and transport (upstream and downstream). Only a very small percentage comes from scope 1 and 2 and supporting activities, such as our offices. As the potential footprint reduction in transport is obvious, it is important to emphasize there is substantial potential in footprint reduction by lowering the need to purchase new load carriers. This can be done by optimizing the usage of the existing load carrier pool (by increasing rotation speed of load carriers and by avoiding loss through digitalisation and traceable load carriers) and by optimising the life span (through proper care, repair, and maintenance). The less new load carriers we need to purchase, the less our impact on the need of wood or other materials to produce them.

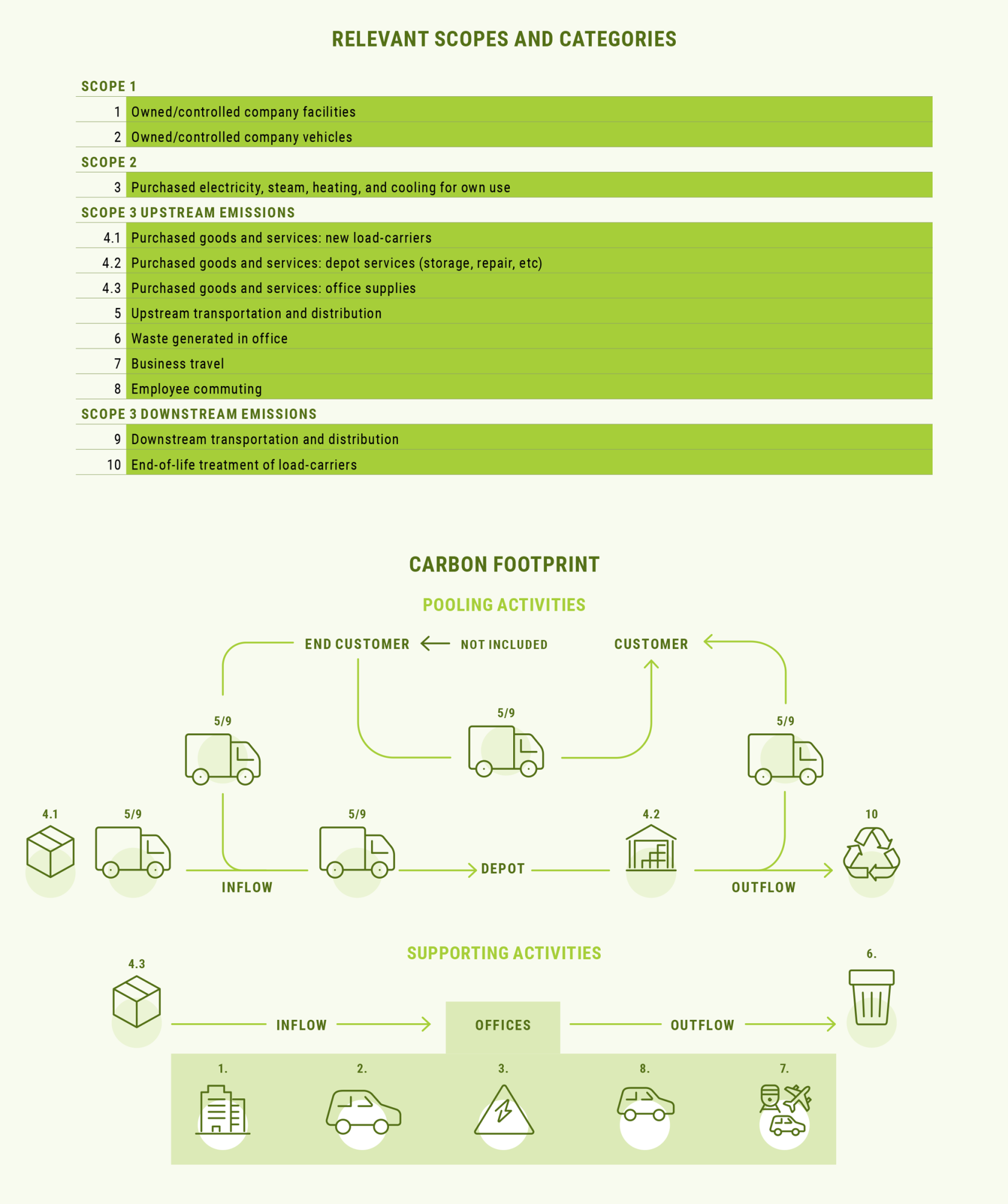

We mapped all relevant Greenhouse Gas (GHG) categories in our business model, which are visualised in the overview below. In this overview we make a distinguishment between supporting activities (which are our offices and employees) and the pooling activities. One of our focus points is improving the data quality of our environmental data.

To do so, we are continuously working on getting more accurate and representative data. One of the ways to do this is by performing a yearly internal audit on the sustainability data, which gives us good input to continuously work on data quality improvements. These improvements lead to better data quality, in some cases also result in (small) adjustments of previous periods.

Material topics are climate mitigation, energy reduction, reduction of air pollution, reduction of the inflow of new materials, outflow of materials and impact on the size and condition of ecosystems. In order to effectively work towards our targets, we are measuring our impact since 2021.

In order to effectively work towards our environmental goals, we have defined our ‘Peak Programme’. This programme helps us to work towards our Faber Development Goals – Climate Action (13), Responsible Consumption (12) and Partnerships (17) and the topics defined in materiality assessment (chapter 2).

Sustainability Progress Report | 2024

chapter four

Environment

Working towards

reducing our footprint.

Next to our Peak Programme we want to maintain a high standard of reducing the environmental impact of our supporting activities, such as our office buildings and car fleet. Also, we contribute to a more sustainable world via donating to tree planting initiatives.

Via these initiatives we offset a part of our carbon footprint. Together with Land Life we help restore land and nature via tree planting programs in Europe. We have now donated more than 100,000 trees in the last four years.

Other sustainability objectives & projects

Improving pallet lifespan is key to our sustainability ambitions. By enhancing repair and reusability, we boost performance. Digitalising assets with Connected Load Carrier helps track and optimise supply chains and reducing loss. Unique identifiers like RFID, QR, and barcodes further enhance control over pallet usage and location.

Even while we are extending the lifetime of load-carriers, they will reach the end of their life span eventually. It is our goal to make sure these decommissioned load-carriers are processed in the best way possible.

IPP Pallet Recovery Communications Campaign

PRS Green Label, which stimulates pallet recovery with converters.

Connected-Load Carrier to make our load carriers traceable.

IPP Pallet Recovery Communications Campaign.

Projects

Impact area 6 & 7

RUDi,

the award winning ReUsable Display from IPP Germany

We believe partnerships and circularity are key to offering our customers an effective and sustainable pooling network. That is why we are creating a sustainable and ethical supply chain with strong suppliers and partners. We do this by stimulating our (new) suppliers to act and improve on sustainability and social topics but also by sourcing in a sustainable manner. Related to the procurement of new-load carriers we are now above 90 % of purchased certified wood for al divisions. Our goal is to work towards 100 % certified pallets in 2030. In 2024, IPP faced a decline in certification due to an one-off urgent pallet procurement to cover customer needs. In 2024 we started a groupwide procurement program to improve the sustainability performance of our supply chain and suppliers.

procurement of new-load carriers

Impact area 5

IPP’s sustainable transport program which has been awarded with the European two-star Lean & Green rating.

IPP France's FRET21 Programme to reduce carbon emissions from transport, see case study here.

PAKi HVO pilot project with our haulier Scholz focusing on green transport solutions, see case study here.

Projects

Reduce transport and depot emissions

Our goal for transport emissions is to improve efficiency, switch to cleaner transport types, but also by optimising our transport network. Depot partners play a vital role in our supply chain. These partners store, sort & repair our load-carriers. Our goal is to help depots in becoming more sustainable and reduce their footprint.

Impact area 3 & 4:

Growing our business and help customers make use of pooling instead of less sustainable alternatives such as one-way load-carriers.

Introduce pooling innovations in one-way load-carrier markets, for example RUDi, the ReUsable Display by IPP Germany.

Projects

Increase the amount of CO₂e-emissions we avoid in the supply chain of our customers. These avoided emissions we call our ‘avoided emissions/Scope 4’ impact: we want to maximise the carbon savings that our customers realise by choosing a pooling system instead of using a less sustainable alternative (such as one-way pallets).

Impact area 1 & 2

Our Peak Programme is two-folded, first focus is to increase Scope 4 (impact area 1 & 2) and secondly, we want to decrease Scope 1, 2 and 3 (impact area 3 - 7). Each Impact Area delivers a contribution to at least one of the Faber Development Goals.

The Peak Programme contains seven impact areas that enable the organisation to minimise the carbon footprint, maximising reuse and engaging in strategic partnerships to reach the sustainability targets. The overview below shows the progress per impact area.

Peak programme

One of our goals is to increase the amount of CO₂e-emissions we avoid in the supply chain of our customers. In other words: we want to maximise the carbon savings that our customers realise by switching to our circular pooling system instead of using a less sustainable alternative (such as one-way pallets or a 1-to-1 exchange system). These savings customers realise we call our ‘Scope 4’.

In order to quantify these scope 4 emissions, we use the ‘Guidance on Avoided Emissions’ from the World Business Council for Sustainable Development (2023 version). Following this guideline we first investigate the savings per trip, which is done via comparative LCA studies. These studies were carried out in 2023 and 2024 according to ISO14040/44 and peer reviewed. The results of these savings per trip can be found in the Faber Group Sustainability Report 2023. Multiplying the savings per rotation by the number of trips on a yearly basis gives the yearly savings we realise for customers. In 2024 we were able to save an amount of more than 40,000 tonnes of CO₂e for our customers, which was an increase of 8 % in comparison to 2023; our aim is to save more than 58,000 tonnes of CO₂e on a yearly basis for our customers by 2030.

Improving our positive impact

As can be seen in the graphs, we have realised an overall lower footprint for our divisions PRS and SATIM, but an increase in absolute CO₂e-emissions for IPP, PAKi and vPOOL. Especially for SATIM the reduction is significant, this is mainly the result of less wood procurement in comparison to previous years. Since we are growing in number of trips and business, it is important to not only look at the absolute footprint, but also to look at the footprint per unit (per trip, barter or m3wood). This is a better indicator for the improvements we realize in our value chain. For PAKi and PRS we see a reduction in CO₂e-emissions per unit in comparison to the previous year and we are also on track to realise our target for 2030. IPP and vPOOL have a higher footprint in comparison to previous years. For vPOOL this has to do with a significant increase in the purchase of new load-carriers. Even though the total footprint for SATIM has gone down, the footprint per m3 wood went up. The main reason for the increase at SATIM is the longer distances trucks needed because new wood logging locations where selected in northern Scandinavia.

Footprint per division

As indicated in the two pie charts – which is a breakdown of our average total footprint over the last four years – the main impact is caused by the production of new load carriers and transport (upstream and downstream). Only a very small percentage comes from scope 1 and 2 and supporting activities, such as our offices. As the potential footprint reduction in transport is obvious, it is important to emphasize there is substantial potential in footprint reduction by lowering the need to purchase new load carriers. This can be done by optimizing the usage of the existing load carrier pool (by increasing rotation speed of load carriers and by avoiding loss through digitalisation and traceable load carriers) and by optimising the life span (through proper care, repair, and maintenance). The less new load carriers we need to purchase, the less our impact on the need of wood or other materials to produce them.

Scope 1: The direct emissions

These emissions are generated by our office buildings and company cars. Examples are gas usage for heating and fuel consumption of company cars.

Scope 2: Indirect emissions

The carbon emissions that are caused by generating electricity that we purchase and use in our own office buildings or company cars.

Scope 3: All other indirect emissions

Emitted in the value chain of the organisation. A distinction is made between upstream and downstream emissions.

We mapped all relevant Greenhouse Gas (GHG) categories in our business model, which are visualised in the overview below. In this overview we make a distinguishment between supporting activities (which are our offices and employees) and the pooling activities. One of our focus points is improving the data quality of our environmental data.

To do so, we are continuously working on getting more accurate and representative data. One of the ways to do this is by performing a yearly internal audit on the sustainability data, which gives us good input to continuously work on data quality improvements. These improvements lead to better data quality, in some cases also result in (small) adjustments of previous periods.

Scope 1, 2 and 3 emissions

Sustainability Progress Report | 2024

Material topics are climate mitigation, energy reduction, reduction of air pollution, reduction of the inflow of new materials, outflow of materials and impact on the size and condition of ecosystems. In order to effectively work towards our targets, we are measuring our impact since 2021.

In order to effectively work towards our environmental goals, we have defined our ‘Peak Programme’. This programme helps us to work towards our Faber Development Goals – Climate Action (13), Responsible Consumption (12) and Partnerships (17) and the topics defined in materiality assessment (chapter 2).